Robust. Reliable. Lowest Total Cost of Ownership

No. 1 Market Share Small Character Inkjet Printer in Japan with Patented Nozzle Capping Technology and In-House R&D Ink Solutions.

Small Character Inkjet (CIJ)

Continuous Inkjet technology is by far the best option for versatile coding application. It is fast, durable, easy to operate, simple to install and, best of all, is extremely versatile as it can print on virtually any surface.

KGK small character continuous inkjet printers (CIJ) are known for industry leading print head reliability, low ink and solvent consumption, durability and reliability, allowing for fewer interventions.

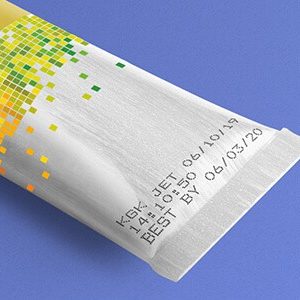

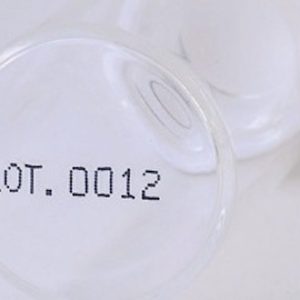

KGK small character continuous inkjet (CIJ) printers can print easy to read text and graphics to enable product identification on a wide variety of porous and non-porous substrates including food, glass, cables and wires, corrugated cases, extruded plastics, lids, metal and plastic industrial parts, metal cans and caps, paperboard cartons, plastic bottles, containers and caps, rubber etc.

Whether to print batch codes, serial numbers, barcodes or traceability information on products and packaging, we will help you select the ideal KGK printers and inks for your production or packaging operation.

KGK Small Character Continuous Inkjet (CIJ)

Printer Series

KGK’s line-up of comprehensive range of robust and reliable small character continuous inkjet (CIJ) printers provide a wide range of continuous inkjet coding solutions to meet every budget, line speed, production environment and substrate material needs.

How Customer Benefits?

KGK series of small character continuous inkjet printers (CIJ) have boosted confidence of many a customer on the reliability and cost effectiveness owing to the patented Nozzle Capping Technology, where the ink and solvent (make- up) consumption is considerably lower and the uptime is very high.

Nozzle Capping Technology

KGK being a “technology-based company”, is continuously endeavouring to refine the high-precision, micro-processing and liquid drop formation technologies.

In continuous inkjet (CIJ) printing the gutter collects the uncharged ink droplets. KGK Jet patented Nozzle Capping Technology automatically closes the nozzle with gutter if the printer is not in use, whilst the ink collected by gutter sent to main tank for reuse resulting in significant saving for our customers.

Whenever the production line is ready, the gutter will change the position to its original location to perform continuous inkjet (CIJ) printing.

KGK patented Nozzle Capping Technology consumes very less Ink and solvent. Additionally, KGK continuous inkjet (CIJ) printers take less than a minute to start. With savings in ink, solvent and faster uptime, our customers can operate for more man hours thus maximizing operations efficiency and minimizing total cost of ownership.

Positive Air

KGK is the only ink jet printer manufacturer to use positive air knives in print head. The positive air kills the static build up that can attract dust and contaminants that ruin print head components.

KGK continuous inkjet (CIJ) printers use air as environmental separation tool to blow off dust and moisture traveling inside the print head.

3 Micron High-Density Ink Filter

For best quality print, one will need high quality inks. Inks must be filtered right to provide high resolution, clear and crisp print graphics. KGK Jet is the only brand which uses 3-micron high-density ink filter for fine filtering of ink during circulation inside the machine.

This fine filtering provides trouble free operation and prevents print defects such as lumps, splatters and spits. The 3-micron high-density ink filter prevents nozzle clogging whilst reducing ink consumption considerably.

Unique Timed Auto Start & Stop Feature

Designed to help customers to start the printer immediately even if the printer has not been operating for a long period. Customers just need to keep the power supply of the KGK printer ON. As per the set schedule time, the printer will start automatically and calibrate parameters such as fluid viscosity and ink delivery systems. No service engineer visit is required resulting in longer up time.

Air Purge System for Every Machine

A dedicated air pump is fitted in every KGK continuous inkjet (CIJ) printer to ensure functionality of the print head is not being affected or damaged by the contaminants from the surrounding environment.

Purging units are essential to maintain a clear boundary path or air curtain between print head and outside environment and also to ensure that the instrument remains clean during prolonged operation. KGK continuous inkjet (CIJ) printers work at their best in dusty and humid environment thus contributing to less maintenance and faster up time.

Unique Nozzle Calibre

KGK Jet continuous inkjet (CIJ) printers are the only ink jet printer equipped with 40µm / 50µm / 60µm Nozzle calibre as compared to higher nozzle calibre available in the market.

Thanks to of KGK Jet in-house know-how of inkjet technology spanning more than 50 years, this unique offering saves substantial amount of ink and solvent during operations resulting in huge saving for our customers.

Video

KGK CCS-3000L CIJ Introduction

CCS-3000L – Printing on Bottles

Video

KGK CIJ Introduction

KGK High Speed Printing

KGK Multiple Messages Printing

Industry Expert in Continuous Inkjet Coding Solutions